Conveying & Logistics

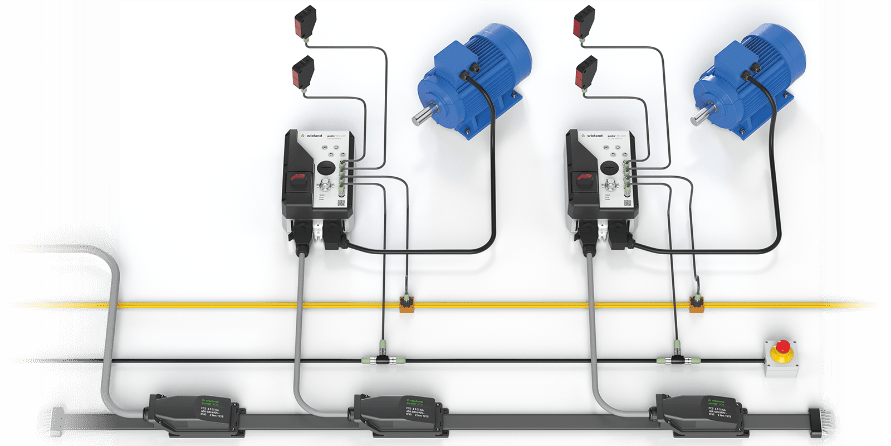

The power distribution of conveying applications using decentralized motor starters can have high maintenance costs, complicated installation, voltage drop over long cable lengths, and require cable replacements anytime a change is needed. Wieland Electric developed a unique flexible power bus tray cable that uses a patented connection technology to solve these problems.

Manufacturing and production facilities can now be more agile and realize changes without a significant investment of labor and materials. On-site diagnostics are also easier to achieve as it is possible to identify and isolate a fault without a system-wide stop. Airports around the world, Heathrow, Pearson, LAX, and MCO are already using this technology for their baggage handling conveyor systems.

WHAT WE OFFER

Podis Power Bus System

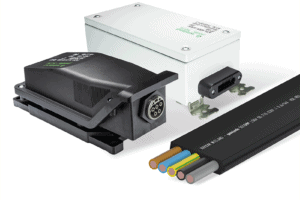

Together with a coded cable, installation is completed quickly and correctly the first time. The copper displacement connection technology allows for a guaranteed and safe electrical connection each time without damaging the conductive core. The terminal pierces the insulation but avoids cutting into the cores, preserving the conductor rating. This allows for changes on the same cable without the need for replacement.

Pluggable Electrical Connectors RST®